Kunststoffverarbeitung & Leichtbau

Plastic processing & lightweight construction

Plastics processing

The processing of various plastics is another mainstay of our flexible production. Different types of thermoplastic processing are among our manufacturing capabilities, such as sawing, cutting, milling, drilling, forming and glueing.

Plastics processing

The processing of various plastics is another mainstay of our flexible production. Different types of thermoplastic processing are among our manufacturing capabilities, such as sawing, cutting, milling, drilling, forming and glueing.

Lightweight

OLU-Preg®

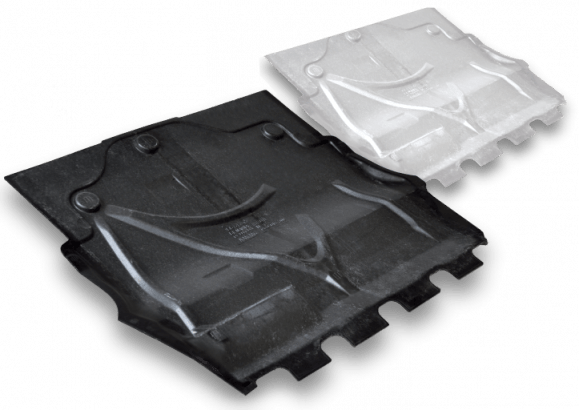

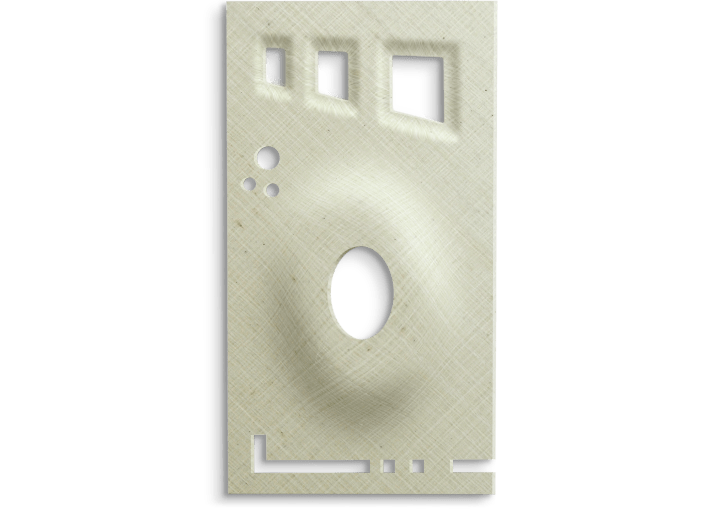

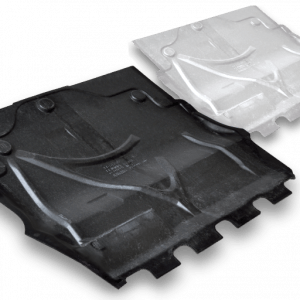

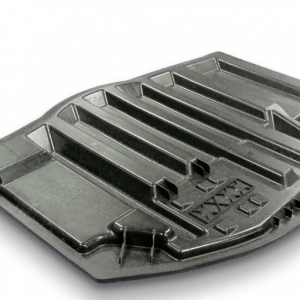

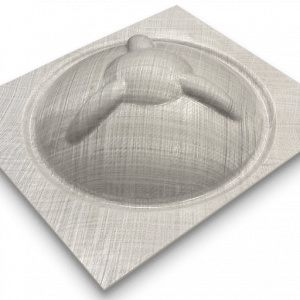

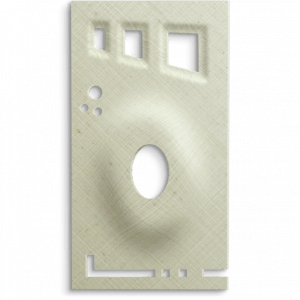

Flexibility and creativity are hallmarks of our successful corporate philosophy. That is why we have developed OLU-Preg®, a lightweight thermoplastic composite that makes it possible to design molded components made of plastic to be lighter yet more robust in order to achieve special customer requirements in the component.

The lightweight NCF organic sheet, illustrates the performance and thus the great potential of this technology. The flexible range of uni-, bi-, tri- and quadraxial glass fiber reinforced thermoplastics allows a wide variety of product designs. In contrast to conventional processes, OLU-Preg® technology produces reinforcing fiber and plastic as a composite directly in the first production process.

- Lightweight composite material

- Excellent deformation behaviour

very good drapeability and easy to thermoform

- Strong composite material

high impact strength and shock energy absorption

- Textile technology for high volume processes

- Cost-effective and energy-efficient manufacturing process

- Recyclable

Lightweight

OLU-Preg®

Flexibility and creativity are hallmarks of our successful corporate philosophy. That is why we have developed OLU-Preg®, a lightweight thermoplastic composite that makes it possible to design molded components made of plastic to be lighter yet more robust in order to achieve special customer requirements in the component.

The lightweight NCF organic sheet, illustrates the performance and thus the great potential of this technology. The flexible range of uni-, bi-, tri- and quadraxial glass fiber reinforced thermoplastics allows a wide variety of product designs. In contrast to conventional processes, OLU-Preg® technology produces reinforcing fiber and plastic as a composite directly in the first production process.

- Lightweight composite material

- Excellent deformation behaviour

very good drapeability and easy to thermoform

- Strong composite material

high impact strength and shock energy absorption

- Textile technology for high volume processes

- Cost-effective and energy-efficient

manufacturing process

- Recyclable

You find more products and detailed information in our brochure OLU-Preg® Datenblatt

You find more products and detailed information in our brochure

OLU-Preg® Datenblatt

Have we piqued your interest?

You can find more information about OLU-Preg® on the following website